As a paper box maker, we process various “post-printing” surface finishes. The most commonly used are foil stamping, UV coating, embossing, or debossing. Though commonly seen, not everyone knows how they work. This is a brief introduction.

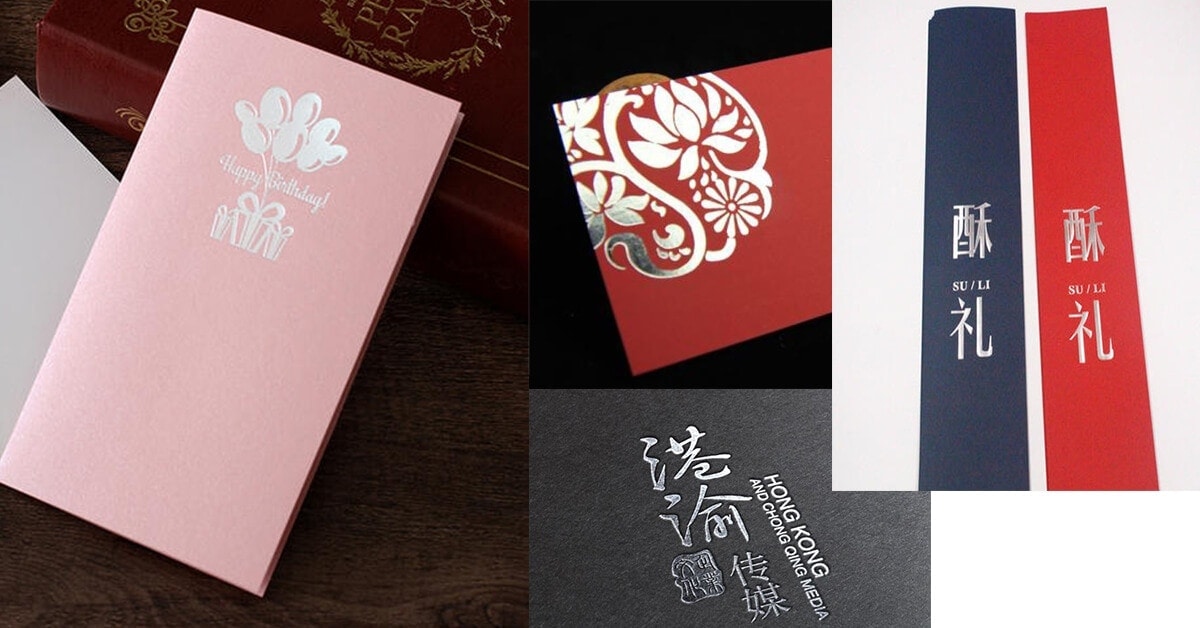

Foil Stamping

Also named as hot press transfer printing, or hot transfer printing for short, it is a method of hot stamping the metal foil on the printed matter with the help of certain pressure and temperature.

Features: Metallic luster and magnificence; various colors available.

Suitable for: Specific words or logos that need to be highlighted.

Note:Foil stamping could work with embossing or embossing, to create a special effect.

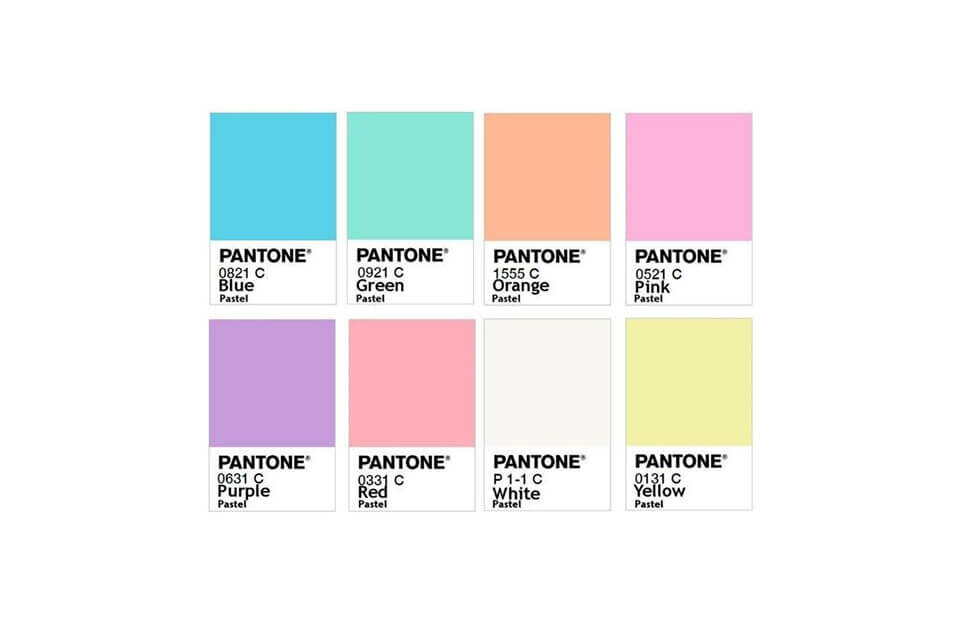

For many people who are not familiar with foil stamping, they may think gold foil stamping is the only color option. Luckily, we have various colors for foil stamping. In addition to the most commonly seen gold, there is silver, red, blue, green, and so on.

Gold Foil Stamp

Silver Foil Stamp

Red Foil Stamp

Purple & Green Foil Stamp

UV Coating

It’s a special process for curing the ultraviolet on the surface of the printed product in full or partially (i.e. spot UV). The ink will be dried and cured by ultraviolet radiation. UV is usually a silkscreen printing process, and now there is also offset printing UV.

Features: A variety of artistic special effects can be presented on the surface of the printed artwork to make it more appealing. UV can be processed together with foil stamping, embossing, or debossing.

Type: Thick UV, matte UV, colorful UV, UV oil with sprinkle colorful powder, etc.

Note: A special UV film is required if we need to process UV on the film lamination, otherwise the UV easily falls off, a bubble occurs, and the glue ruptures.

Spot UV Coating

Embossing / Debossing

It’s also called imprinting. It is a process of forming patterns on the substrate by pressure. After the metal plate is corroded, it becomes a pressing plate and a base plate for pressing. There are two kinds of plates: ordinary corrosion plate (which is cheaper) and laser embossed plate (which is more expensive).

Embossing

A convex template (male template) is used to emboss a three-dimensional relief-like pattern on the surface of the printed matter through pressure, creating a visual impact.

Suitable for: Paper of more than 200 GSM

Note: A better embossing effect could be achieved when combined with foil stamping or spot UV.

Embossing

Debossing

A concave template (female template) is used to impress the surface of the printed matter into a concave relief-like pattern. The printed matter is partially recessed to make it three-dimensional and cause visual impact

Suitable for: Paper of more than 200 GSM

Note: A better embossing effect could be achieved when combined with foil stamping or spot UV. An extraordinary artistic effect is expected if the concave template is heated and applied to special hot melt paper.

Debossing

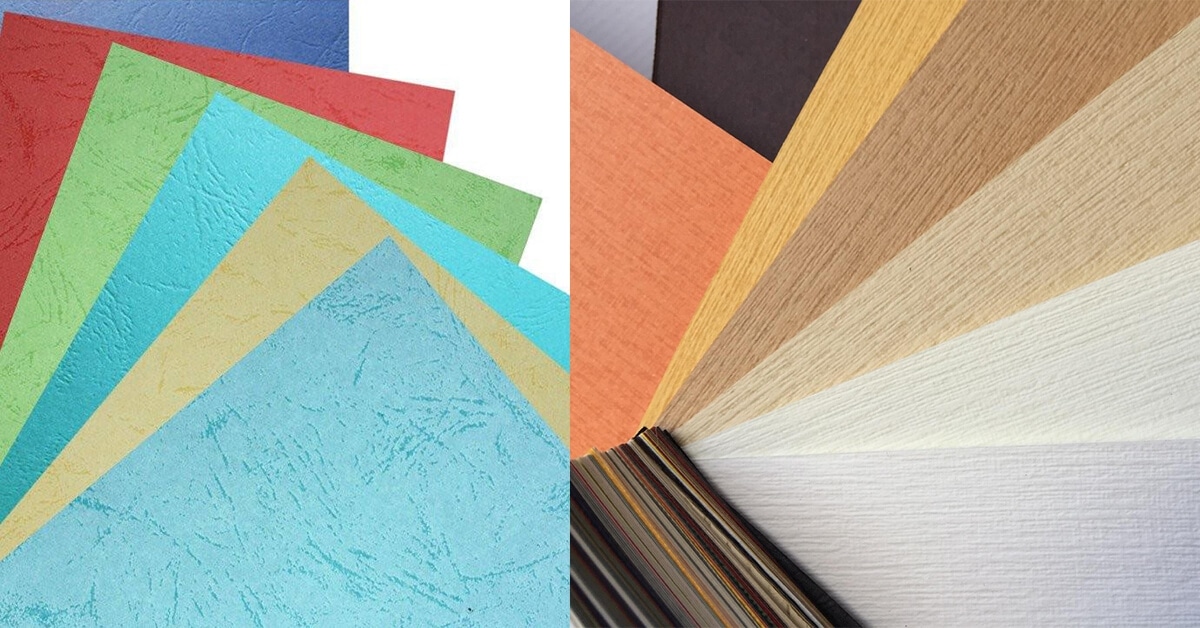

Special Textured Paper

A metal roller with engraved lines is pressurized to leave a full-page texture on the paper surface, producing paper with strong decoration and unique style. We can use this textured paper to make paper boxes and paper tubes.

Special Textured Paper