Among the numerous packaging materials, paper and cardboard have a long history and occupy a considerable proportion in the packaging industry. The reason why paper material has such a great development potential is that it has incomparable performance compared with other materials and can meet the requirements of various commodities. For example, paper and cardboard are recyclable, printing and branding friendly, great in protecting products, and good for mass production. With the development of society and the prosperity of new products, the need for innovative paper packaging structures constantly grows.

Application of materials

The commonly used paper materials for cardboard boxes include whiteboard paper, yellow board paper, and colored paper. Coated whiteboard paper is used most frequently in commodity packaging.

In the selection of materials, the first consideration should be given to the form of product-to-be-packed. Are they moist goods, wet goods, liquid goods, or solid goods? Are they high-fat goods or frozen goods? We must pay attention to quality protection, safety, operation, convenience, transportation conditions, and so on.

The design requirements

Convenience:

Paper boxes must be designed to be easy to produce, easy to store, easy to display and sell, easy to carry, easy to use, and easy to transport.

Protection:

Protection is the key to the paper structure design. According to the different characteristics of different products, the design should be considered separately from the lining, arrangement, shape, and other structures, especially for products with easy damage and special appearance.

Variability:

It is very important to update and change the appearance of the paper container modeling structure, which can give people a sense of novelty and beauty, and stimulate consumers’ desire to buy.

Scientific rationality:

Being scientific and reasonable are the basic principles in design. Scientific and reasonable paper containers require less material and provide large capacity, strong resistance, and full function with a lighter weight at low costs.

Classification

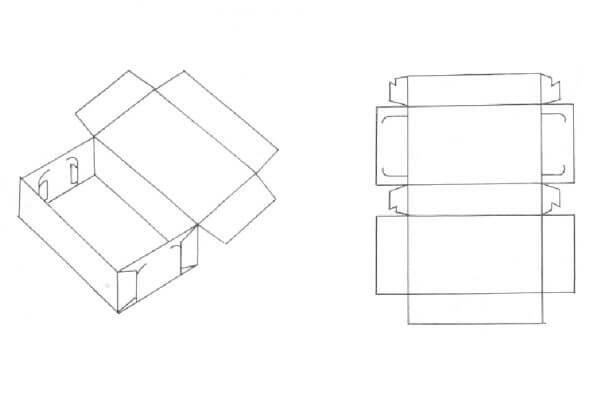

Folding cartons and fixed cartons are the two most commonly used in carton packaging.

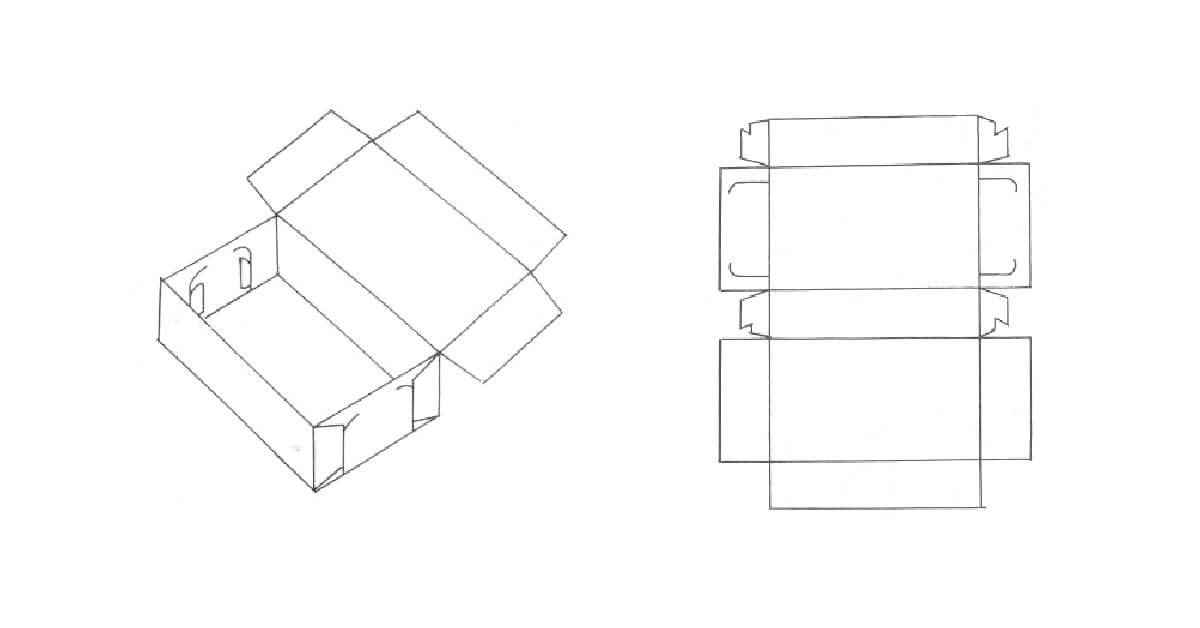

In terms of box types, folding cartons are usually divided into three categories: cylinder type, dish-shaped type, and other types with special structures. In terms of box structures, folding cartons come with a plug or lock type, paste type, and assembly type.

Fixed cartons include telescopic cartons, mounted cartons, padded cover cartons, odd-shaped cartons, drawer cartons, shoulder-mounted cartons, hinged cartons, tilting cartons, percussive cartons, in-box cartons, special product cartons, latticed cartons, cartons with inner partition, etc.

(A) Folding cartons

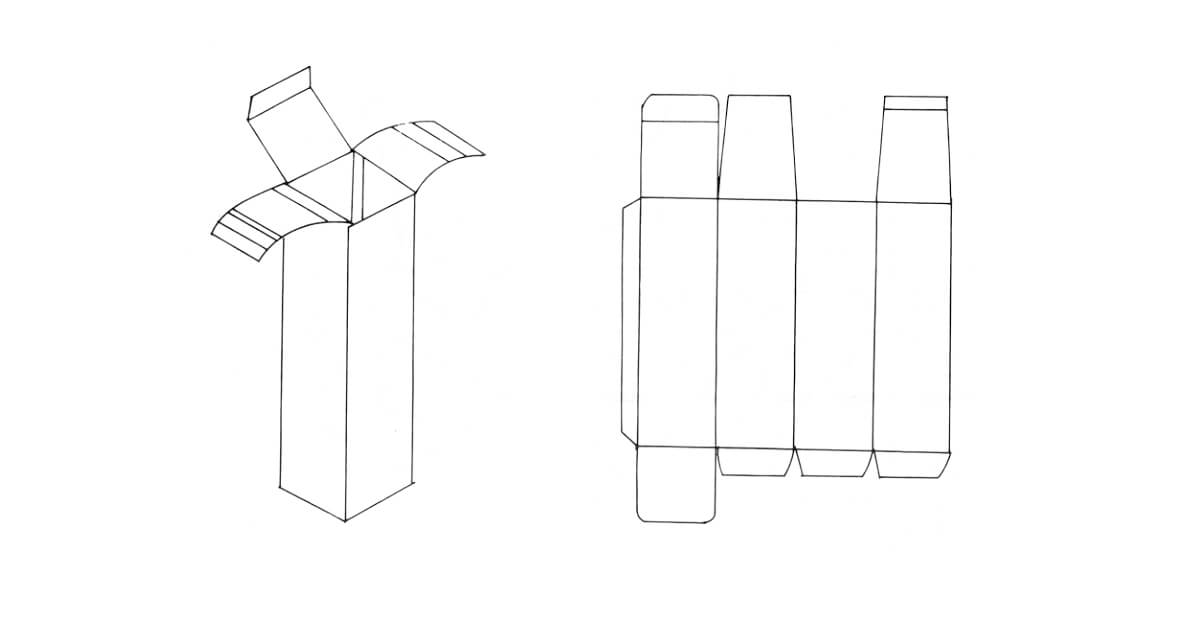

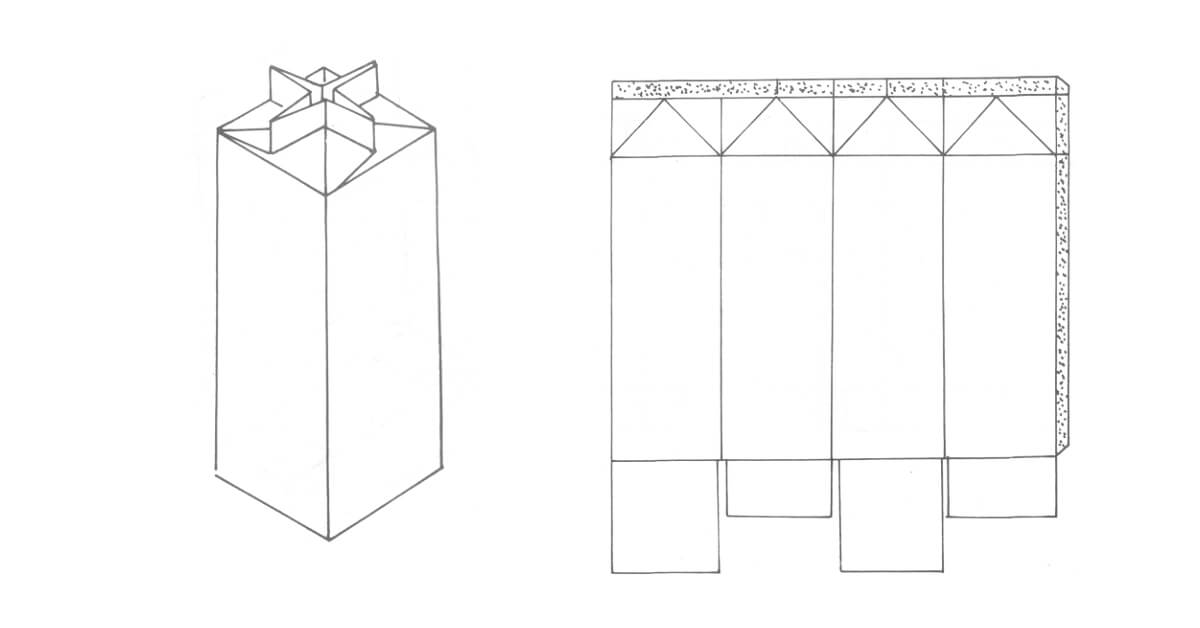

Cylindrical box: a folded paper box with high shape, side bonding, and open ends.

Cylinder-shaped box for bottles, side bonded, bottom bonded, and top inserted.

Rectangular food box with top insert and bottom insert, side sealed.

Completely closed box, all sides are bonded by the adhesive method. The cover and bottom are also completely sealed.

Composite box: bottom, top, and side are sealed by sticking.

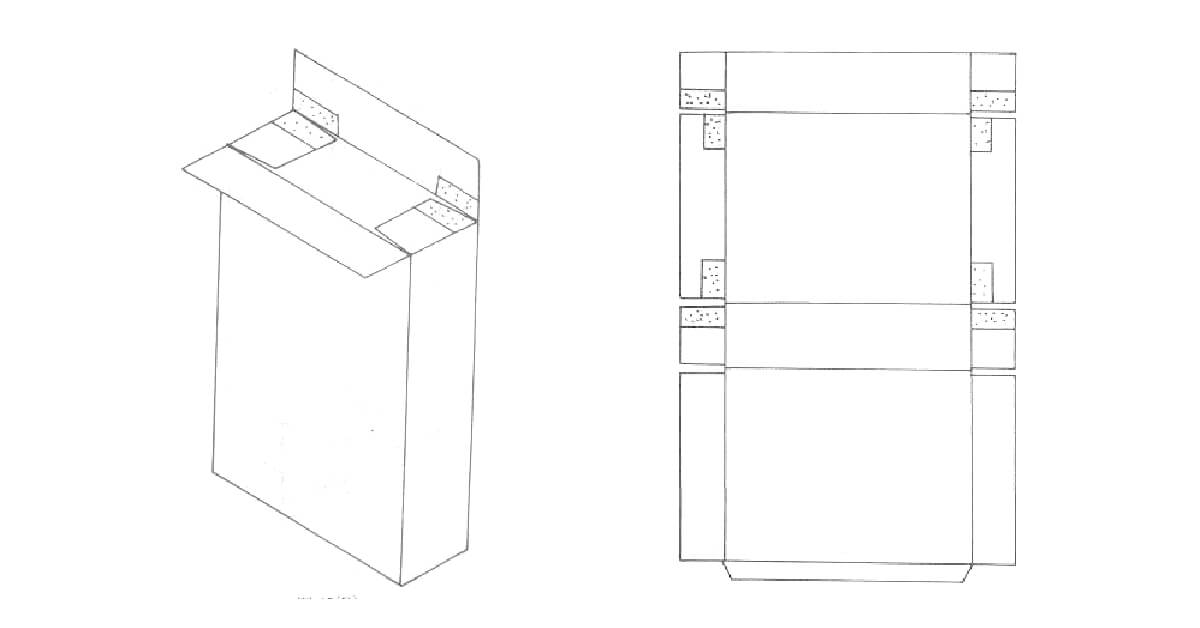

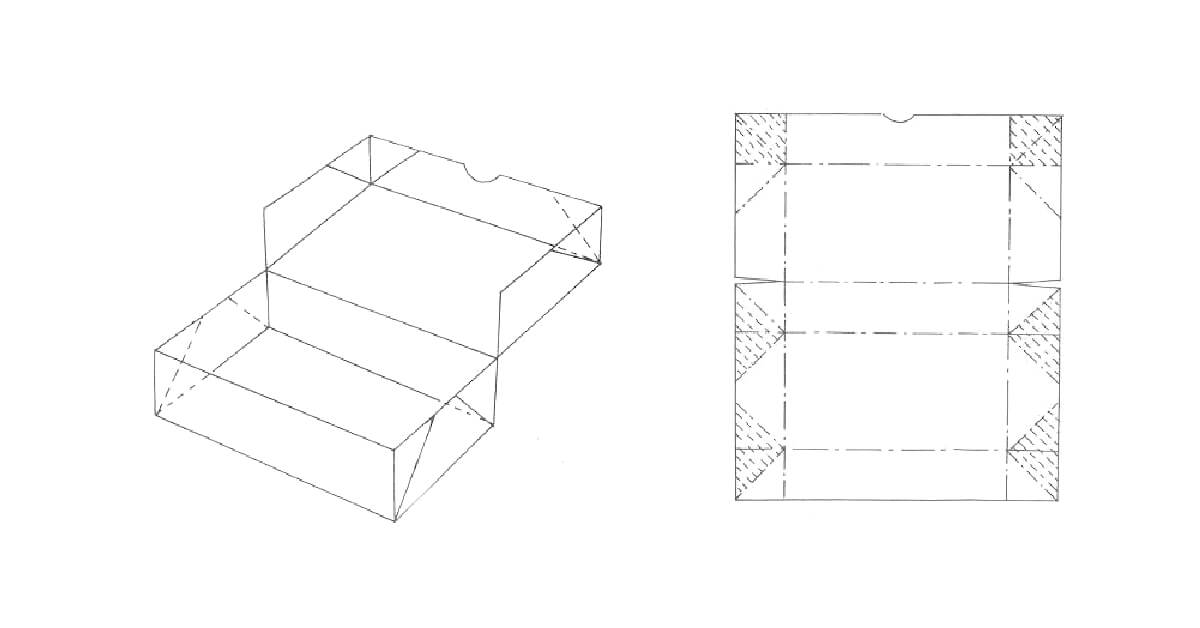

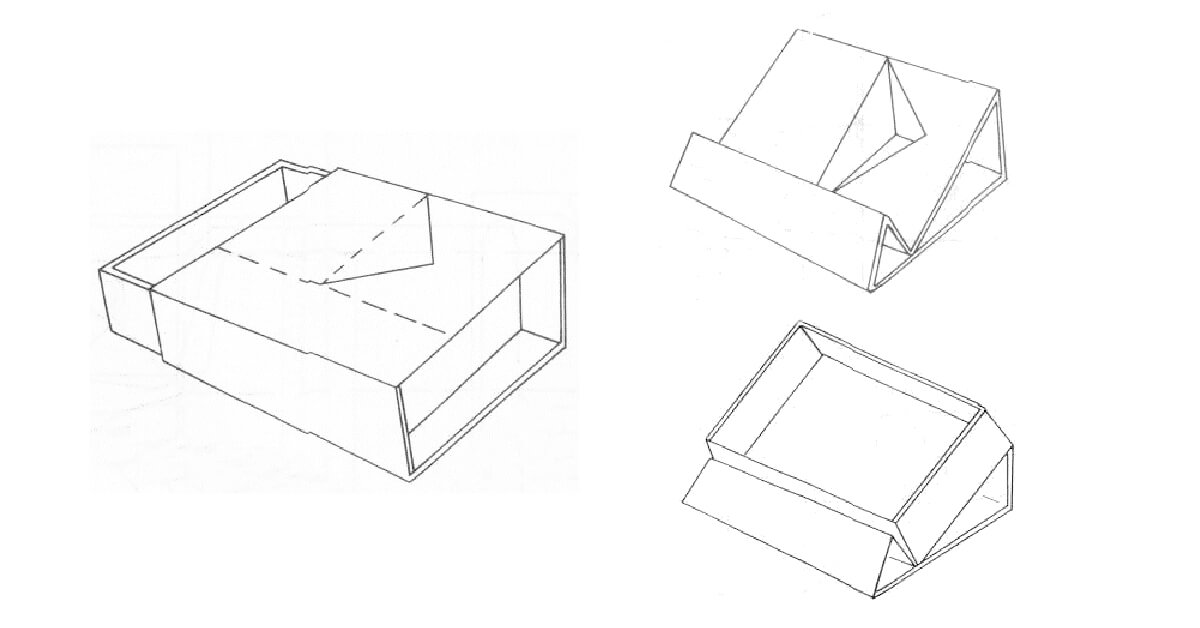

(B) Dish-shaped boxes: a box with a lower modeling facade like a dish.

Socket type dish-shaped box with lid connection and corner of the box using locking method.

Folding dish-shaped box with six corners being sealed.

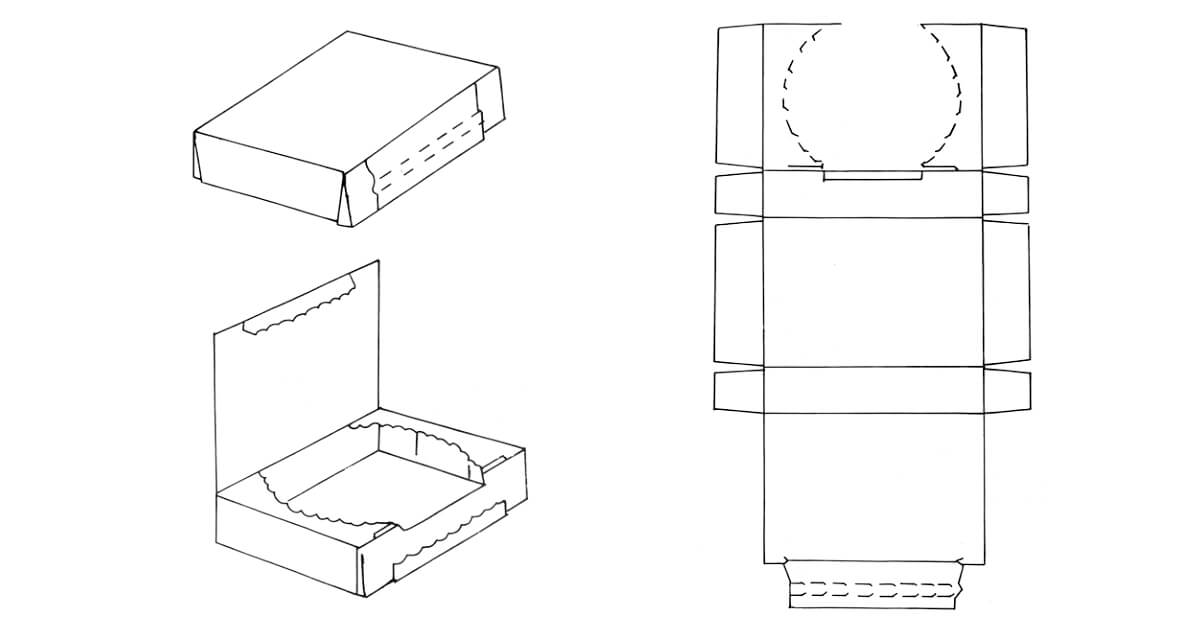

Folding box with four corners sealed and with an oval window in the middle for display, dotted line on the cover, and fully sealed when packing. It can be opened along the dotted line when used.

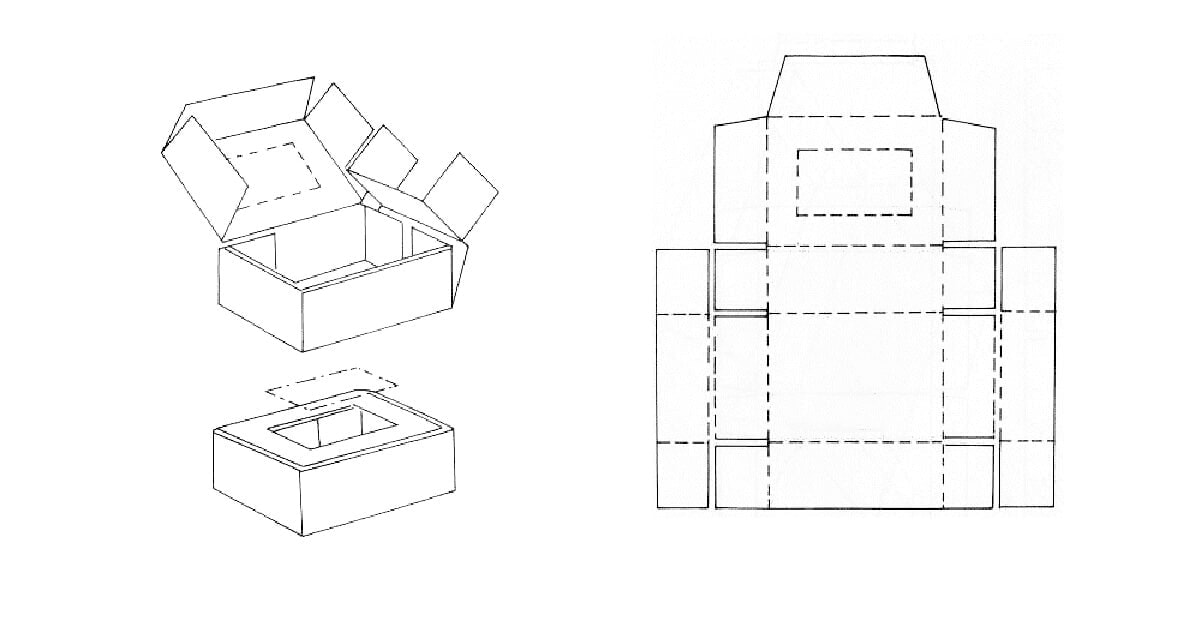

Assembly box with two to three layers of sidewalls and a rectangular dotted line on the cover surface for the purpose of removing food.

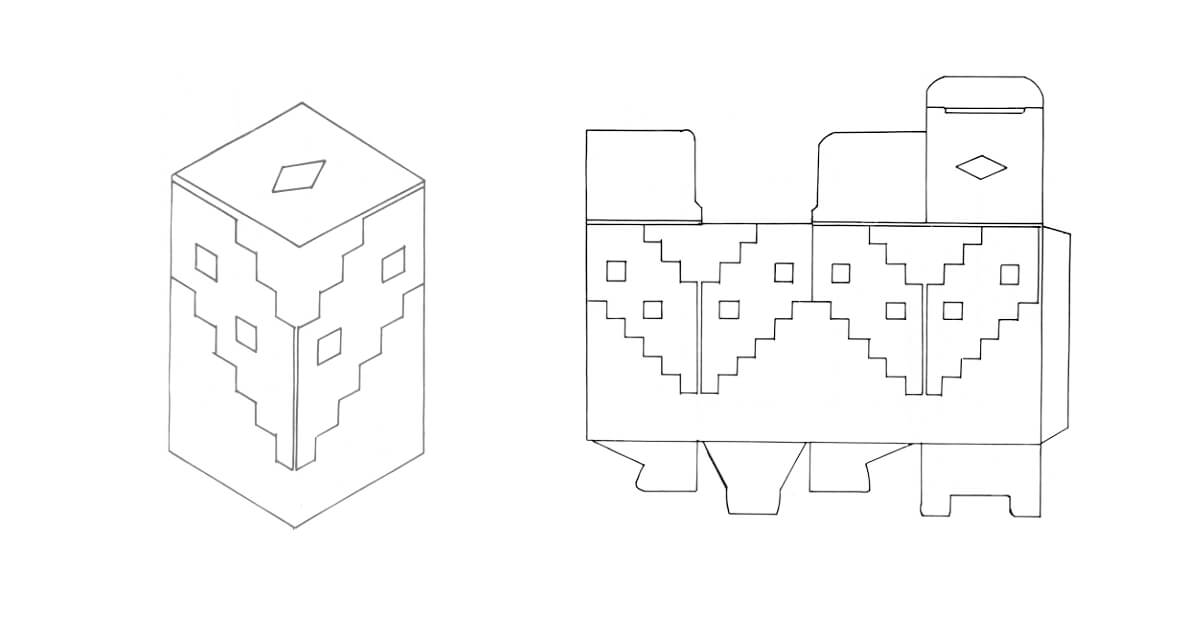

(C) Other types with special structures: different from cylinder types and dish-shaped types.

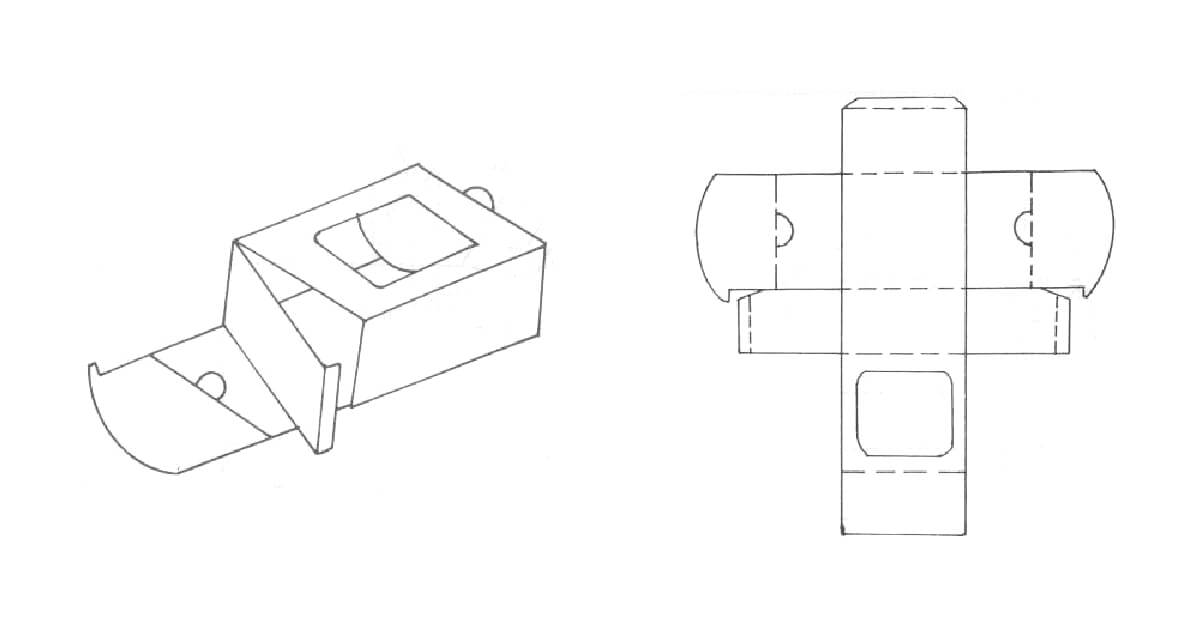

Windowed box, double layer overlapping sealing of cover plate, with a window on the ceiling plate for the display of goods and access hole.

Display box. The box in the picture is composed of an inner box and an outer box.

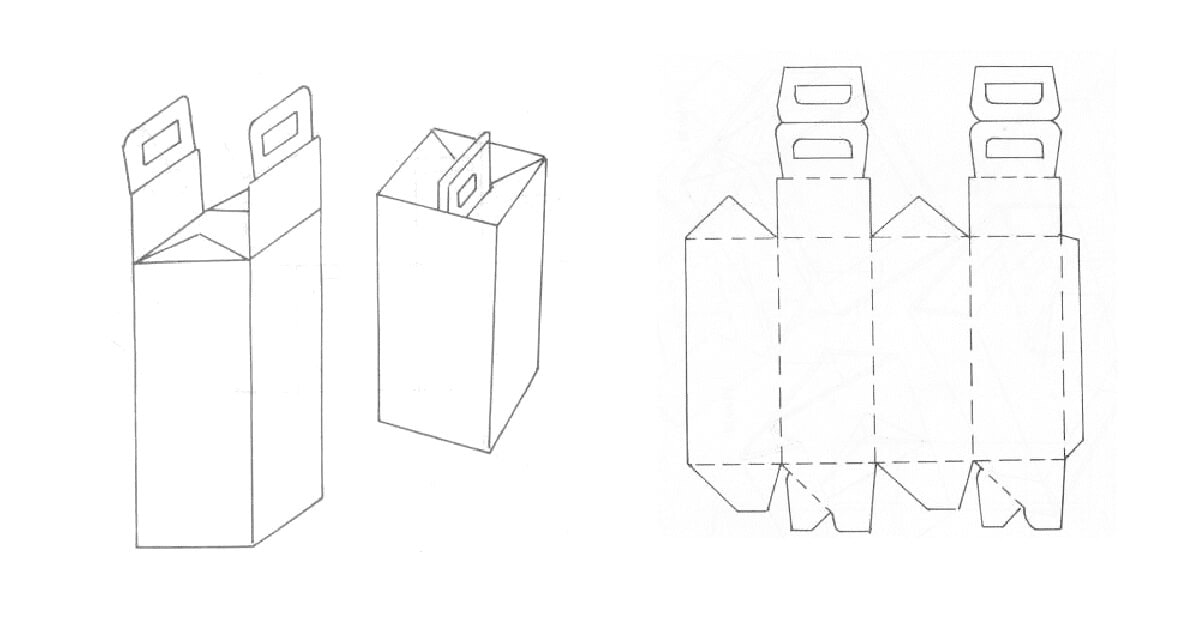

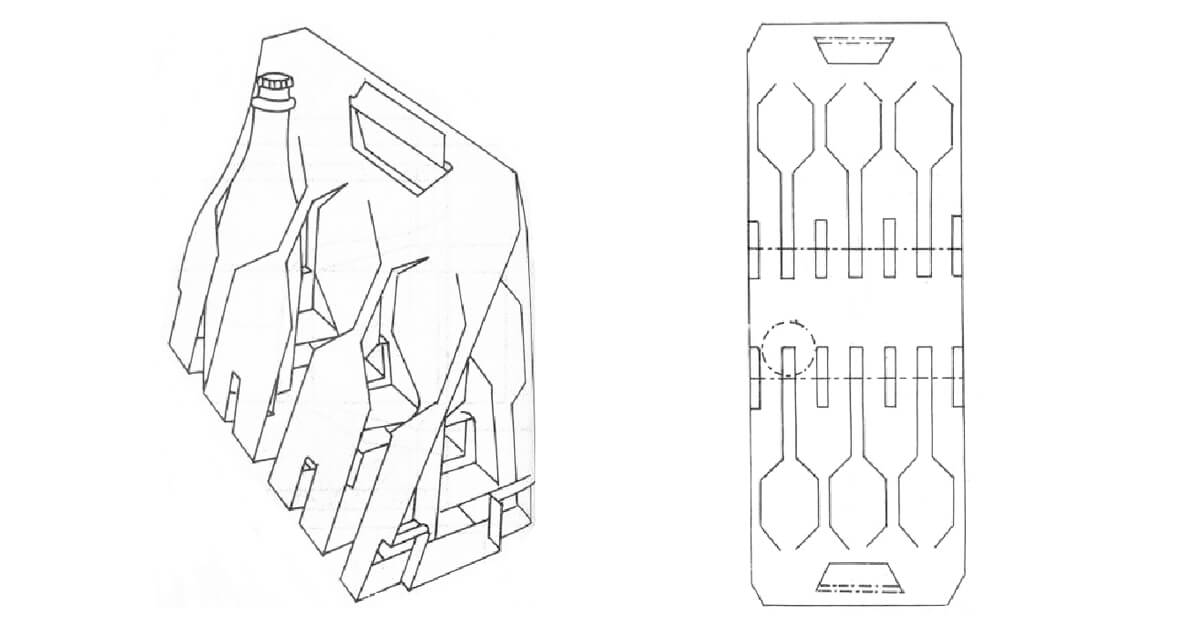

There are also many kinds of hand-held boxes, especially in the packaging of food. It is easy to carry.

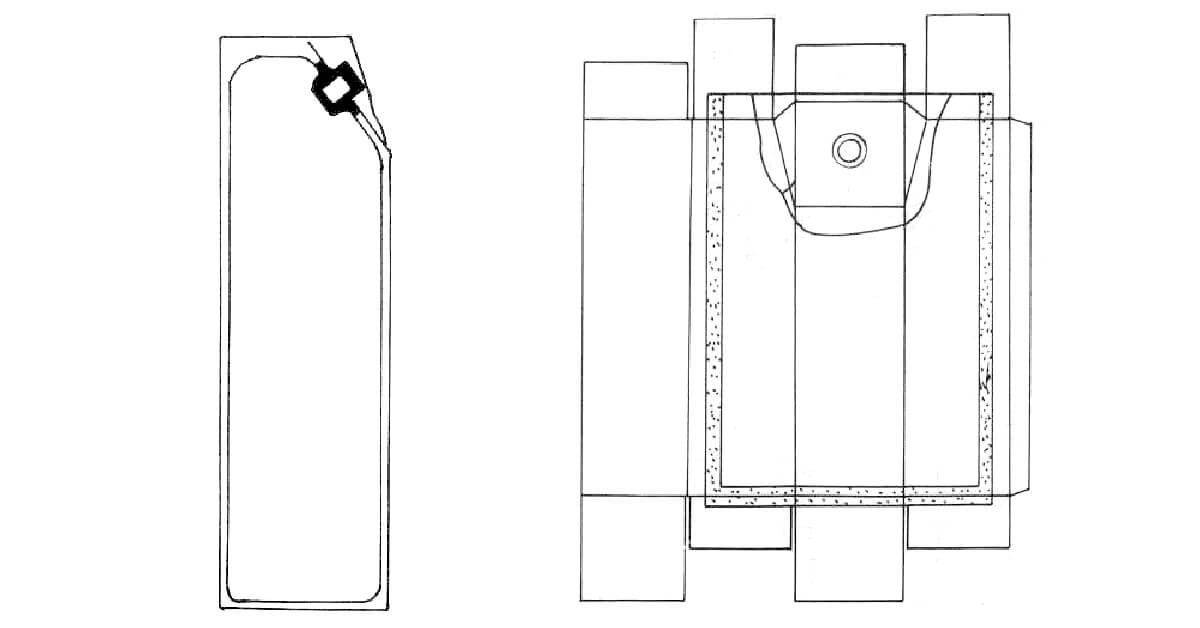

The liquid box usually consists of an inner bag, sealed paper box.

The term “collection box” refers to the conditional package of several products with different specifications and varieties but related to their use.

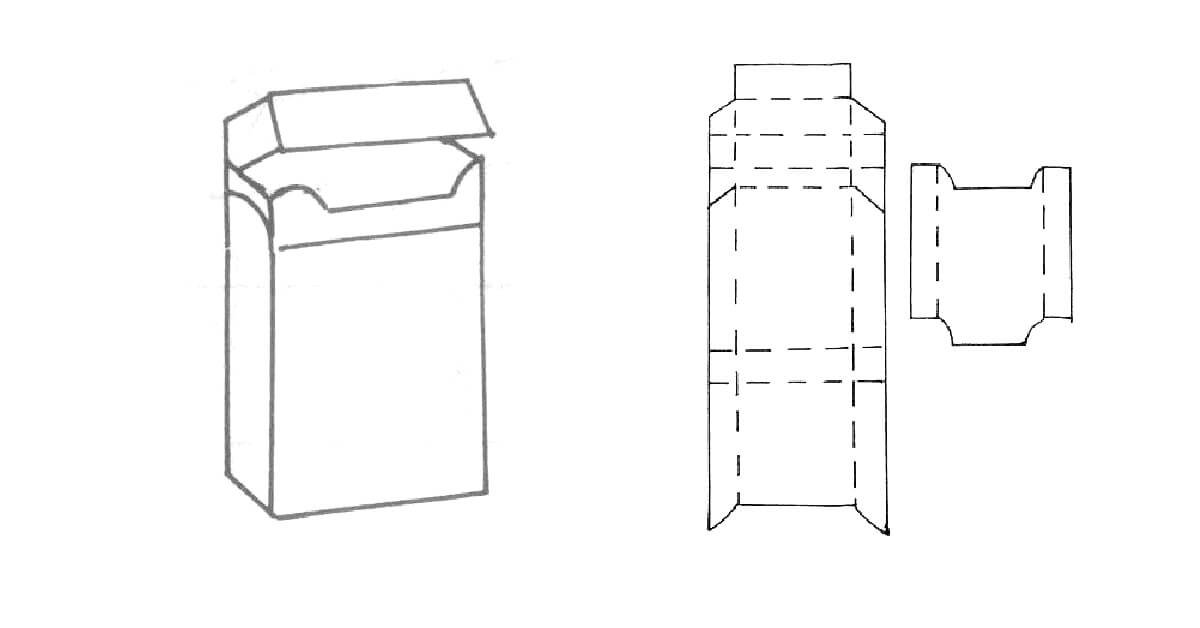

A cigarette box is a self-packing box with a simple and easy opening method.

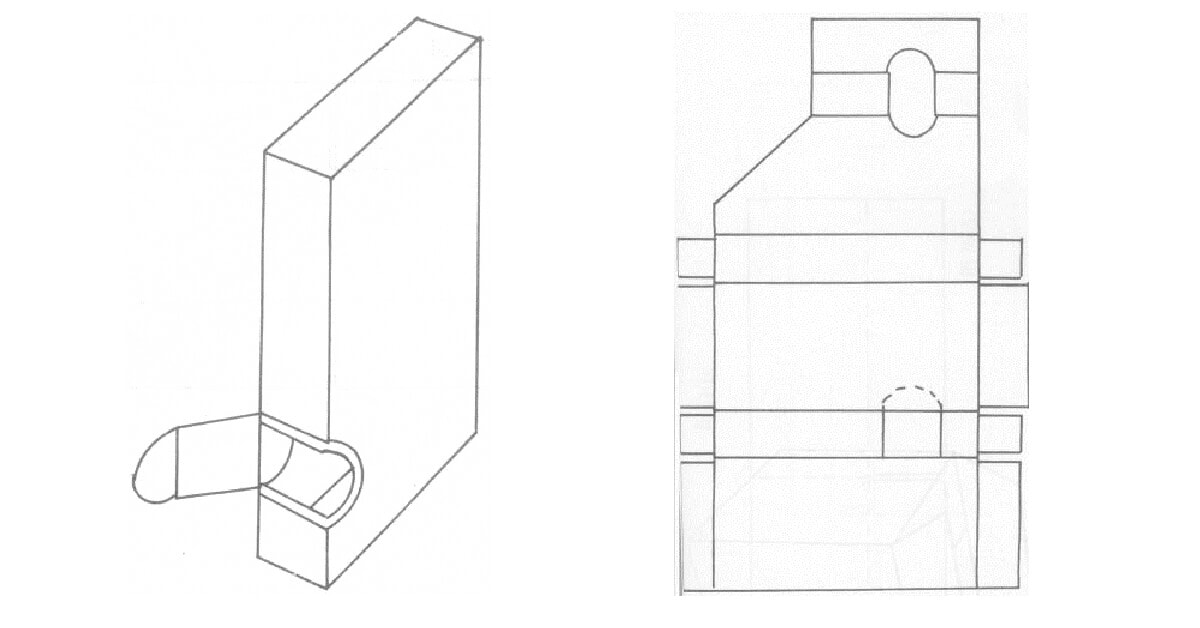

A vibrating outlet box is a packaging box specially designed for powder and granular items.