The switch to paper packaging is the recent-year-trend among global marijuana businesses. Then along comes paper packaging questions for packaging manufacturers, marijuana producers, product retailers, and even marijuana end-users.

Have you ever been confused by a wide variety of paper materials? What paper is used for CBD packaging? How is paper packaging material measured in weight and thickness? Which paper material has the right thickness/weight for your packaging needs?

To answer these questions, we’ve finished this guidance about paper THICKNESS AND WEIGHT to help you better understand paper measurements and some common types of paper packaging solutions.

Definitions of Paper Thickness, Paper Weight, and Measurements

Although people often talk about paper thickness in weight, these two measurements are not necessarily proportionate for some reasons: various material densities, different reference standards, changeable producing processes, etc. The out-of-proportion situation is why we would like to explain paper thickness and weight as separate components in this article.

What is the paper thickness and how it is measured?

People often measure the thickness with calipers, given in units of points/mils in the United States and microns in the other areas. (1 pt.=25.4 mic) Length units offer more direct thickness results without computing if leaving aside paper density and paperweight.

- Points (pt.)/Mils

One point, abbreviating as pt., equals a thousandth of an inch. Hence a standard 16 pt. cardstock is as thick as 0.016 inches and 14pt.= 0.014 in. while 12pt.= 0.012 in.

An easy method to know how thick the cardstock measured in pt. is to move the decimal over three spots to the left.

- Microns (mic)

Micron is a paper thickness unit used internationally. One micron equals a thousandth of a millimeter, and reasoning can be 1000mic=1mm.

Micron is a more sophisticated measuring method than point or mil since one micron is much smaller than one point. It would be easier to make numerical value contrasts on different thicknesses.

Sometimes it can be confused if you want to know the basic weight of paper through calipers because two kinds of paper material in different weights can have the same thickness. The good thing is that paper thickness measurements offer you a better understanding of unfamiliar cardstocks by comparison with your familiar products.

What is paper weight and how it is measured?

When it comes to paper weight, there are two commonly used measurements: one is U.S. basis weight (pound), and the other one is the international metric system (grammage).

Although it seems a little complicated or confused, pound measurement widely existed (especially in the United States) before ISO 216 Paper-Sizing System became international.

- Pounds (Lbs/#)

The pound measurement is sometimes perplexing because different paper grades can have the same weights. The first thing to understand this point is to know how it is measured.

The pounds of paper refers to the “basic weight” of a ream paper—the weight of 500 sheets of uncut/basic-sized papers before cutting into commercial selling sizes. For example, the “basic sheet size” of bond paper is 17*22 inches.

What’s interesting is that various paper materials have different sheet sizes. And this leads to a result that the thin wax paper can have a higher pounds than white cardstock. Another example is that white cardstock of 8.5*11 and 11*17 can both be 80 lb/#.

In this regard, trying to make clear which is the heavier paper material between papers with the same pounds is not an easy process for us. GSM measurement, however, provides convenience.

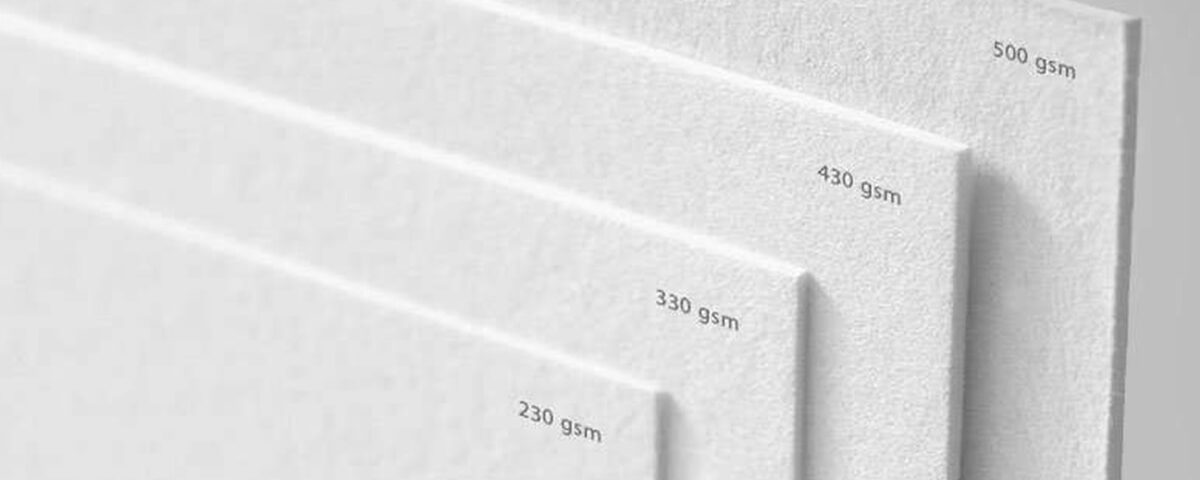

- GSM

GSM is the abbreviation form of Grams per Square Meter, used to describe the weight of a sheet of paper that measures 1m*1m. Simpler than pound measurement, you can directly understand which paper is heavier and thicker—the higher GSM represents the thicker material.

Table 1. GSM of some Common Paper Products

| Newspaper | 35-55gsm |

| Office paper | 90-120gsm |

| Posters | 130-250gsm |

| High-grade magazines | 260-300gsm |

| Business cards | 350-450gsm |

So, what are the weights of the common types of paper packaging materials?

We gathered several detailed paper packaging materials and collated them into the following readable charts. All charts give priorities of international units of GSM and Microns for comparison purposes.

Table 2. Commonly Used Paper Packaging Materials: Thickness & Weight Ranges

| Paper Materials | Metric | Microns | Points | Pounds |

| Kraft paper | »105gsm | »254mic | » 10pt. | 30-40 lbs. |

| paperboard | ≥180gsm | ≥304.8mic | ≥12pt. | ≥50 lbs. |

| corrugate | 1000-1100gsm | 1100-10000mic | 20pt.-82.5pt. |

Common Available Paper Packaging Materials and their GSM & Micron

- Linerboard

Linerboard, also named containerboard, is specially produced for making corrugated boards. In most cases, the linerboard is naturally light-brown in line with the colors of unbleached wood fibers.

Table 3. Linerboard Types: Thickness & Weight

| GSM | Microns | |

| Liner A1 | 150.1gsm | 232mic |

| Liner A2 | 171.7gsm | 268mic |

| Liner A3 | 195.3gsm | 305mic |

| Liner A4 | 249.5gsm | 392mic |

| Liner A5 | 275.7gsm | 420mic |

| Liner A6 | 293.9gsm | 476mic |

| Liner B1 | 370.4gsm | 600mic |

| Liner B2 | 277.1gsm | 427mic |

| Liner B3 | 437.1gsm | 725mic |

| Liner B4 | 206.3gsm | 327mic |

| Liner B5 | 393.1gsm | 663mic |

| Liner B6 | 167.0gsm | 260mic |

| Liner B7 | 323.8gsm | 524mic |

| Liner B8 | 149.6gsm | 229mic |

- Solid Bleached Sulfate C1S Whiteboard

Solid bleached sulfate (SBS) whiteboard is a type of card stock that is heavier, thicker, and more durable than office papers. It is made from bleached chemical paper pulps and often in natural white color. C1S Card stock has a glossy mineral or synthetic pigment coating(s) on one side.

Table 4. SBS C1S Whiteboard: Thickness &Weight

| GSM | Microns | PT |

| 210gsm | 270mic | 10pt. |

| 230gsm | 300-310mic | 11pt. |

| 250gsm | 330mic | 12pt. |

| 300gsm | 400-41mic | 14pt.-16pt. |

| 350gsm | 470-480mic | 18pt.-20pt. |

| 400gsm | 550mic | 22pt.-24pt. |

- Solid Bleached Sulfate C2S Whiteboard

Similar to the SBS C1S whiteboard, C2S Card stock has glossy mineral or synthetic pigment coatings on two sides.

Table 5. SBS C2S Whiteboard: Thickness & Weight

| GSM | Microns | PT |

| 80g | 60mic | |

| 105g | 80mic | |

| 128g | 100mic | |

| 157g | 120mic | |

| 200g | 170mic | |

| 210g | 210mic | |

| 230g | 250mic | 9pt.-10pt. |

| 250g | 265mic | |

| 300g | 350mic | 12pt.-14pt. |

| 350g | 410mic | 16pt.-18pt. |

| 400g | 465mic | 20pt |

- Art Paper

Art paper is a high-quality printing paper coated with a matte or gloss finish to enhance smoothness, glossiness, or printing effect.

Table 6. Coated Art Paper: Thickness & Weight

| GSM | Microns |

| 105gsm | 90-100mic |

| 128gsm | 120-130mic |

| 157gsm | 160mic |

| 200gsm | 190-20mic |

| 250gsm | 250mic |

| 300gsm | 310mic |

- Chipboard

Chipboard, made of recycled papers/fibers, often has more than three layers: a layer of chipboard, two to three layers of coating on the outer side, and one on the reverse side.

Table 7. Chipboard: Thickness & Weight

| GSM | Microns | PT |

| 342gsm | 406mic | 16pt. |

| 350gsm | 432mic | 17pt. |

| 361gsm | 456mic | 18pt. |

| 381gsm | 508mic | 20pt. |

| 400gsm | 533mic | 21pt. |

| 420gsm | 559mic | 22pt. |

| 454gsm | 610mic | 24pt. |

| 488gsm | 660mic | 26pt. |

| 513gsm | 686mic | 27pt. |

| 711gsm | 711mic | 28pt. |

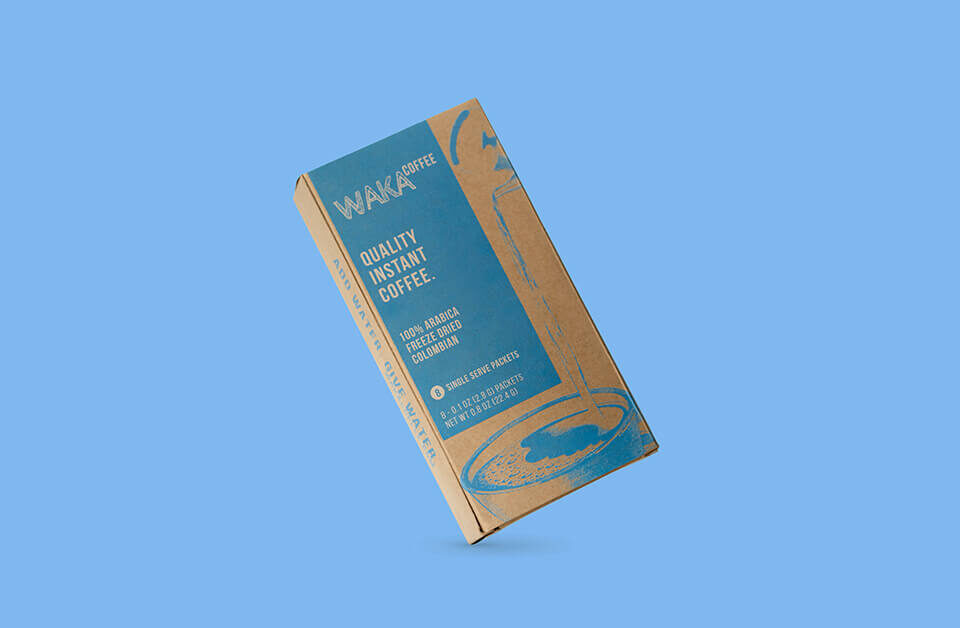

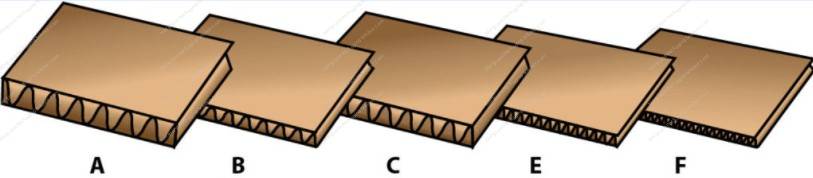

- Corrugates

Corrugated boxes are commonly used mailing/shipping packaging solutions for almost all industries. They are recyclable and durable and usually consist of three layers: two layers of craft linerboards plus a middle layer of fluted craft paper. What distinguishes corrugated boxes in different protection levels are the three types of flutes (A flute, B flute, C flute, E flute, and F/micro flute).

The letters of the flute names do not represent a level relationship but relate to their invented order, referring to flute numbers per linear foot.

Table 8. Standard Single Wall U.S. Corrugated Flutes

| Flute numbers (per foot) | Flute Thickness | |

| A Flute | 30-36 | 3/16 inches |

| B Flute | 44-50 | 1/8 inches |

| C Flute | 36-42 | 5/32 inches |

| E Flute | 86-94 | 1/16 inches |

| F/Micro Flute | 121-129 | 1/32 inches |

The C type appears the most frequently used for corrugated mailing boxes among these flutes; the B flute allows a lower cost while the F flute provides an excellent printing surface.

If you still want more durable corrugate packaging, multiple layers called double/triple wall flutes are available to add strength.

What do these numbers mean for you?

Seeing all these tables and numbers may be daunting to you. But it is always wise to think ahead when choosing packaging solutions for your products. Light card stock can never be the packaging answer for fragile or heavy goods.

In the long-term run for your business, the right packaging help in reducing the damage rate during delivery processes.

Start-ups and companies with little packaging knowledge can have a direct consultation with your cooperative packaging manufacturers or ask for samples. The easiest way to understand which paper material fits best to your products is to talk to a packaging pro.

Send us an email at [email protected] with your packaging needs and questions, our packaging experts are always pleased to reply.