We believe sustainable packaging is the future of all packaging materials.

Why not using a unique custom cylinder packaging for your marijuana products?

In this post, we will provide you with a complete guide to customize your paper tubes.

Let’s dive right in.

Quick Fact:

Keep looking for unique and eye-catching packaging is an endless topic for many cannabis brands.

You are probably switching your packaging from plastic, mylar bags, glass jars, and vials, to folding cartons, to rigid boxes and odd-shaped ones.

The footprint for pursuing new packaging never stops.

Take a look, and you might gain some inspiration from this post.

Chapter 1: Why Paperboard Packaging?

Photo courtesy of Unplash.com

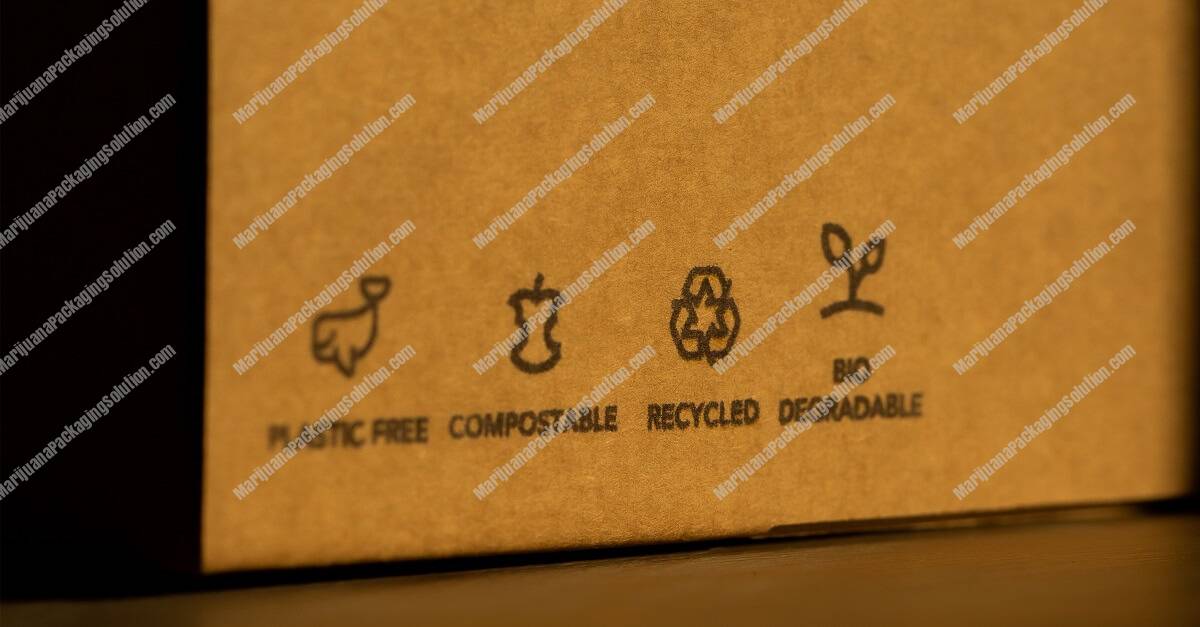

1 Paper Packaging Reduces Litter And Landfill.

The need for going eco is even eager these years. The earth is suffering from packaging waste, trashes, and in-biodegradable items and rubbishes in a vast amount daily.

More brands and enterprises have started to seek sustainable products, including packaging.

2 Reusable And 100% Compostable

Paperboard tubes are made of paper and are biodegradable.

After consuming the products it carries, you can use the paper tube for other use. Even it’s trashed, it can be fully degraded and won’t harm our earth.

Made from renewable sources, the usage of paper-based packaging will provide us with a sustainable, healthy, and safe environment, among other many benefits.

3 Better Brand Image If You Are Using A Paper Packaging

Paper packaging is a sustainable, renewable resource that comes from trees.

Around 96% of paper packaging in the United States is recovered. Almost all of it is recycled to make new boxes and other paper products.

More than six in ten people surveyed would purchase products packaged in paper or cardboard so they can reuse the packaging.

78% of respondents to a Paper and Packaging survey conducted by Ipsos said they are more likely to buy products packaged in paper and cardboard since they are better for the environment.

(Resources:https://www.inc.com/paper-and-packaging/five-reasons-why-paper-based-packaging-is-the-go-to-solution.html)

4 Cost-saving And Easy To Custom

Different from custom plastic or glass containers, cardboard cylinder packaging is easy to customize.

It has a relatively lower MOQ to customize, which is very friendly for new companies or startups.

It usually has a lower price compared to printed plastic containers or glass packaging.

5 Strong, Sturdy Yet Light-weight As Secondary Packaging

Cylinder box packaging tubes come from rigid thick paperboard, which offers strong protection for the product they carry.

Strong paperboard cylinders could even be used as shipping material. Yet, such strong material is also lightweight, which is user-friendly as retailing packaging.

Chapter 2: Why Cylinder Packaging Box?

Photo courtesy of Unplash.com

1 The Round-shape Is Unique Compared To Boxes, Jars, Plastic Containers

Unlike other rectangle paper boxes, a round-shape paper cylinder packaging can better fit cannabis bottles, concentrate jars, cartridges, wax containers, and flower glass bottles.

They are ideal for packaging small glass bottles, like hemp oil dropper bottles, CBD oil bottles, vape pens, CBD salves containers, and so on.

2 Can Be Used For Your Full Catalog To Ensure The Best Branding Consistency

The exciting part is that you can almost use cardboard tube packaging in different sizes and designs to pack your different products.

For instance, a slim mini tube for vape cartridges, a short and wide paper tube for wax concentrates, a big tube for cannabis flower glass bottles.

All of them are in different designs, but they are all round-shaped cardboard tubes.

It’s an exciting packaging idea, especially for retailing market.

Now that we’ve seen the advantages of using cardboard tube packaging for your cannabis-related products let’s explore how a tube is made.

After this tour, you will have a clear idea of cardboard tube packaging and easily customize your own.

Chapter 3: What Is Cardboard Cylinder Packaging And How To Custom Paper Tube Packaging?

Before diving deeper, let’s take 2 minutes for a short video, and you will have a clear mind of how to make a paper tube (literally, “handmaking” a tube)

1 What Is A Printing Paper Tube, And How Is It Made And Assembled?

A custom printing cardboard cylinder packaging tube is made by wrapping and gluing a printed art paper onto a plain cardboard tube surface.

The artwork we see on the round tubes is not printed directly onto the tubes. It is actually printed on a thin art paper and wrapped on the tube body.

To help you better understand, let’s disassemble a tube and see how it is formed up.

A printed paper tube consists of 4 parts:

- Two pieces of paper discs (top disc & bottom disc)

- A paper tube body

- An inner tube (in 3-piece-tube style only)

- A printed wrapping paper

All of them are made of thick paperboard and can be glued with a printed art paper.

By different cutting and adding extra tubing, we can make paper tubes into different variations.

Photo courtesy of Jeff Cheng (MarijunaPackagingSolution.com)

1.1 How To Make The Paper Tube Body Structure?

Step 1: Rolling And Gluing (The Process Of Deciding The Tube Diameter)

We use a metal mold with a machine to roll and glue different paper layers into a thick paperboard.

There are several layers of paper rolled, pressed, and glued to each other, ensuring the stability and strength of the paperboard.

That’s why the paper cylinder packaging is rigid and sturdy.

Different metal molds are made with different diameters. That’s why we can customize the tube diameter according to your requirements.

Step 2: Wrapping Blank Paper Or Printed Artpaper Onto The Tube Body (No Matter If You Need The Tubes To Be Printed, Or Generic)

After rolling and gluing the cardboard tube body, the original tube body can’t be used as packaging, since we can still see the rolling and gluing lines and traces on the tube surface.

So we need to cover them with nice-looking paper, both blank or printed.

Moreover, the tube body itself is not printable due to its round shape, so we use machines, or labor, to wrap and glue the printed art paper onto the tube surface.

The printed art paper itself is the carrier of all kinds of printing & finishing processes.

Step 3: Cutting (The Process Of Deciding The Tube Height)

After the adhesive in the tubes is dry, we use a cutting machine to cut them into the appointed length (according to customers’ needs).

That’s why you can customize the tube height.

Step 4: Assembling

After cutting the paper tube into different sectors, we will assemble the tubes with the paper discs and other add-ons, like foam inserts, paper inserts, child-resistant mechanisms, etc.

1.2 How To Make The Top And Bottom Paper Disc?

1 Press Several Layers of paper to form up a thick paperboard

2 Glue a printed art paper onto the thick paperboard

3 Cut the round shape of the paper disc out of the paperboard

Glad that you’ve seen how a tube is formed up and cut into shapes, now we will show you more tube styles.

With some production tricks and tips, we can make paper tubes into different styles.

Here we go!

2 Three Types Of Cylinder Tube Body Structure

Photo courtesy of Jeff Cheng (MarijunaPackagingSolution.com)

1-piece paper tube

Such tubes have only one piece of the tube body; it usually comes with a lid that is not paper, for instance, metal lids, plastic lids.

We can see such tubes in most tea or coffee packaging; you can also custom such tubes for flower packaging with an aluminum foil inner surface.

2-piece paper tube (telescoping tube)

Such tubes are widely known as the telescoping tube. They are similar to the typical lid and base boxes.

There are two pieces of tube body in such tubes; the lid is usually wider than the base.

So when the tube is assembled, the lid covers parts of the base.

3-piece paper tube

Such tubes have 3 pieces of the tube sectors.

They have a tube base, a tube lid, and an inner tube embedded in the lid or base, allowing the lid to connect.

We also call it the “neck” or “shoulder” of the tube for the inner tube.

3 Five Main Paper Cylinder Packaging Tubes Structure Styles

Photo courtesy of Jeff Cheng (MarijunaPackagingSolution.com)

Among these three tube body structures, we can divide them into 5 popular packaging structure styles:

1 Full Telescope Style #1: Short lid & tall base

3-piece structure tube type. The lid is shorter than the outer base.

After assembled, no neck/shoulder (inner tube) exposed outside.

2 Full telescopes style #2: Tall lid & short base

3–piece structure tube style. The lid is taller than the outer base.

After sealed, no neck/shoulder (inner tube) exposed outside.

3 Full telescopes style #3: Equal height lid & base

3-piece structure tube style. The lid is equal height to the outer base.

After assembled, no neck/shoulder (inner tube) is exposed outside.

4 Tubes with exposed neck/shoulder (Lid-off Tubes)

A 3-piece paper tube structure.

After assembled, the neck/shoulder (inner tube) will be exposed outside.

The 2-piece tube structure comes with a relatively broader cap and a narrow base.

After resembling, the lid will be fully covered.

4 Three Kinds Of Paper Materials You Can Use For The Cardboard Tube Body

As mentioned in the last chapter, we use regular paper to roll and glue to form up a thick tube body; you can also choose what paper material to form up the tube body.

Photo courtesy of Jeff Cheng (MarijunaPackagingSolution.com)

1 White & grey cardboard

- It’s the most popular cardboard material for paper tube packaging

- It has a look between white and grey

- The material is famous for its strength and stability.

2 Kraft cardboard: it’s recyclable material; the uncoated kraft paper has a natural look and is very attractive for brands that seek a more nature-look product.

3 All-black cardboard: black paper usually has a more luxurious look. It is widely used in brands that require pure-black packaging.

5 Three Kinds Of Paper Materials You can Use For Wrapping The Tube Body

Photo courtesy of Jeff Cheng (MarijunaPackagingSolution.com)

1 Coated art paper (Most popular)

Coated art paper is the most used material for the paper and packaging industry. It’s also known as coated white paper.

It has the widest customization for printing and finishing. You can use full-color printing, Pantone color printing, gold foiling, emboss/deboss, UV, and so on.

2 Kraft Paper

Kraft paper is also called brown paper. It’s getting more and more popular due to its natural and raw look.

It’s an uncoating paper printed with CMYK or PMS color system, gold foiling, UV, etc.

However, due to the natural brown paper color it carries, you should be careful with color choice when you want a kraft tube.

3 Fancy Paper

One of the widely used fancy papers is all-black paper.

There are also many kinds of fancy paper you can choose from, like gold paper, silver paper, leather-like paper, paper with a special texture, etc.

They are mostly for luxury packaging.

6 Two Different Paper Tube Opening Edge Treatment Styles For The Inner Tube

Photo courtesy of Jeff Cheng (MarijunaPackagingSolution.com)

1 Rolled Edge

A rolled edge refers to a production treatment adapted in the inner tube of a 3-piece paper tube structure.

The smooth-cut opening looks more tidy and clean. It can also prevent scraping or scratching even if you open and close the tube frequently.

The disadvantage is that it will add up extra width to the “entrance” of the inner tube so that the product might shake in the tubes during transportation.

Yet, if you choose rolled edges, we suggest adding a foam or paper insert to stabilize the product better.

2 Unrolled Edge

Unrolled edge is easier to be scraped if opening the tube lid too often.

But the most significant advantage of tubes without a rolled edge is that they won’t add up extra width to the inner tube’s “entrance.”

In other words, there will be no extra room inside walls so the products it carries won’t shake or waggling in the tube. It protects the product better.

Chapter 4: How To Custom Print Your Paper Tube Packaging?

Hurray! Now we have an obvious vision about a paper tube, and I am sure you have got to know which kind you are interested in.

Now let’s make it even more interesting for you,

If you decide to use paper tube packaging and stand out from the competitor, we offer all kinds of customization to help you achieve that.

1 Four Major Used Printing & Finishing Methods For Cardboard Cylinder

1 CMYK (Full-color Offset Printing) + PMS (Pantone Color Printing)

2 Foil Stamping (Gold foiling)

3 Spot UV

4 Silk Screen Printing

Photo courtesy of Jeff Cheng (MarijunaPackagingSolution.com)

2 Three Popular Paper Coating And Lamination Methods

1 Glossy

2 Matte

3 Soft-touch, Satin

Photo courtesy of Jeff Cheng (MarijunaPackagingSolution.com)

3 Three Most Popular Add-ons And Inserts For Paper Tubes

1 Foam insert

2 Paper insert

3 Blister pack

Photo courtesy of Jeff Cheng (MarijunaPackagingSolution.com)

Chapter 5: Five Best Cylinder Packaging Tubes For Marijuana Packaging

1 Custom Printing Cylinder Packaging For Vaporizer Packaging

Cardboard cylinder packaging is an ideal packaging solution for vaporizer packaging.

With the help of a foam or a paper insert. You can customize the tube into any height & diameter according to your cartridge dimension.

We are also proud to recommend our certificated CR vape cartridge paper tube.

Photo courtesy of Jeff Cheng (MarijunaPackagingSolution.com)

2 Custom Printing Tubes Packaging For Cannabis Concentrates

Imagine your tiny little concentrate jar be stored and protected in a nicely designed cylinder packaging tube. This can be exciting, right?

Suppose you are using a childproof concentrate jar, congratulation! You can custom a concentrate packaging tube in a smaller and mini size.

If your dab jars are not child safe and need a child-resistant concentrate packaging tube, we can make it for you.

Photo courtesy of Jeff Cheng (MarijunaPackagingSolution.com)

3 CBD Tincture Packaging Tubes

You might be customizing your CBD tincture bottles, dropper bottles by applying printed labels onto the glass bottle.

Secondary packaging is essential for your branding. Use these CBD tincture packaging tubes to add more branding and marketing information printed on them.

Photo courtesy of Jeff Cheng (MarijunaPackagingSolution.com)

4 Cannabis Flower Packaging Paper Tube

The flower packaging paper tube can be tailored into large sizes no matter what primary packaging for your cannabis flowers.

You can use the tube for your flower glass jars, reversible cap vials, and push down & turn vials.

Photo courtesy of Jeff Cheng (MarijunaPackagingSolution.com)

5 Cannabis Pre-roll Cylinder Packaging Tube

Pre-roll paper tubes are a perfect match for cannabis pre-rolls, joints, and blunts.

Try a super slim paper tube for your single pre-roll, king-size joint, or a wider tube for 3 pre-rolls, 5 pre-rolls using a paper seperator.

And as always, we can make it child-resistant if you need it.

Photo courtesy of Jeff Cheng (MarijunaPackagingSolution.com)

Voila! Congratulation on finishing this article.

We hope this guide will show you the lovely part of a paper tube.

Once you start the customization, never hesitate to speak to our packaging consultant and let us make things easy for you: [email protected].

Or simply fill the below contact form: